Highly interesting

Technical specifications are only valid for those products classified as first choice. Consequently, any failure to conform to such standards with respect to all other commercial types shall not be considered as grounds for complaint.

Porcelain Tile

Characteristics:

Product with very low water absorption, high mechanical performance, chemical and frost resistance. It is suitable whether for using on interior or exterior floors of residential and commercial buildings. Special pieces normally employed are skirting tile, staircase step and gradone.

Floor Tile

Characteristics:

“Gres” floor tiles is the most common name for dry pressed, glazed ceramic floor tiles with low or medium-low water absorption manufactured by single firing. It is suitable whether for using on interior or exterior floors of residential and commercial buildings. Complementary pieces usually include inserts, triangles, skirting tiles, staircase step and borders.

Wall Tile

Characteristics:

“Azulejo” is the traditional Spanish name for dry pressed, glazed ceramic wall tiles with high water absorption manufactured by single or double firing. Their characteristics make them especially suitable for using on interior walls of residential and commercial buildings. Complementary pieces usually include decors, borders, and mosaics.These tiles offer the possibility to reproduce any texture or pattern for decorative purposes. They are covered with a vitrified glaze which may be white or plain-coloured.

Fixing

- Ensure that the size, shade, colour and quality of the material is that of what was expected.

- Mix pieces from several boxes to achieve a uniformed mixture.

- If the material is porcelain, there is no need to submerge the tile in water as there is no absorption.

- The surface to be tiled on must be flat, rigid, absorbent, textured, cohesive, dry and clean of dust and dirt.

- Any additional layers such as water proofing, levellers, sound proofing, under floor heating must be taken into account when choosing the correct adhesive.

- Recommended adhesives for porcelain tiles are those with C1 or C2 (UNE-EN 12004) features with a high adherence, indeformable, and high resistance to water. Adhesives for products with low or zero absorption.

- The adhesives used for wall tiles should be selected according to the substructure and the external environment of where it is being used. Wall tiles that are absorbent can be fixed by all different tile fixing methods.

- We recommend the Thin Layer Method of tile installation. The C1 or C2 adhesive should be spread uniformly with a metal trowel that is suited to the tile size. With the Single Thin Layer Method, adhesive is only applied to the surface of where the tile is to be fixed. With the Double Thin Layer Method, adhesive must be applied to both the rear side of the tile as well as the surface of where the tile is to fixed. This method is recommended for tiles that are greater than 40x40cm, in areas of high pedestrian traffic, façades, in exteriors and always when fixing porcelain tiles.

- Read and follow the instructions of the adhesive manufacturer with regards to amount of water needed to mix the adhesive and time in which it must be used.

- Use a trowel with uniform teeth.

- Do not fix under any circumstances using the Dot and Dab Method of fixing. It is highly important that a uniform spread of adhesive is used over the entire tile. It is also recommended to use guides or spacers between the tiles (spacers of 1.5mm to 5mm are available on the market) which can be used to facilitate the uniform separation of the tiles.

- Tile fixing or grouting should not be carried out when temperatures are below 5ºC and caution has to be followed when temperatures are above 30ºC due to the fast drying times of the adhesive.

- Do not walk on floor tiles during the drying time of the adhesive. It is recommended to wait for at least 48-72 hours before walking or applying any weight on the tiles.Clean and vacuum the spaces between the tiles before grouting.

- Interlocked laying (maximum 25%)

- Strict observance of the 1.5mm minimum joint between floor tiles is essential, with a wider joint being recommended for medium and large formats, thus allowing absorption of the differential pressure produced in the multi-layer floor/adhesive/tile system.

Maintenance

During fixing:

Once the tiles have been fixed, it will be necessary to provide adequate protection against possible damage during subsequent building work, covering them with cardboard, thick plastic or a layer of sawdust. Cleaning after fixing:Residues remaining after work completion can be easily removed with a commercial detergent or an acid-based one, always considering the chemical resistance indicated by the manufacturer.When using cleaning products the following general considerations should be taken into account:

- Acid cleaning should never be carried out on recently laid floor tiles. The reaction of the acid with the unset cement may damage the joints or deposit insoluble compounds on the surface.

- It is recommended to soak the surface with clean water before using any chemical agent. This prevents the grouts from absorbing these agents. Clean the surface with water immediately after the treatment to remove any remain of the chemical products.

- Trowels and abrasive scourers must not be used. The use of sponges is strongly recommended, especially natural ones.

- The fixing by a professional tiler is highly recommended for getting the best performance.Routine care:Daily cleaning of stoneware tiles is particularly simple, it only requires clean water to which an alkaline base cleaner may be added.The use of waxes, oils or similar products is not recommended since the non-porous glazed surface prevents from a correct application.It may occasionally occur that stains cannot be fully removed with a commercial detergent, making necessary to use solvents or specific cleaning agents. It is recommended to firstly check the chemical resistance of the tile and, as an extra precaution, test in a clean, spare tile or in non-visible area.

Important:

Hand-painted ceramic wall tiles or complementary pieces on third and fourth firing must be treated with extreme care during both the fixing and subsequent cleaning, as well as during ordinary routine cleaning. The use of pure or diluted acids, detergents or other corrosive products will seriously harm their original look.

Fixing large sized tiles

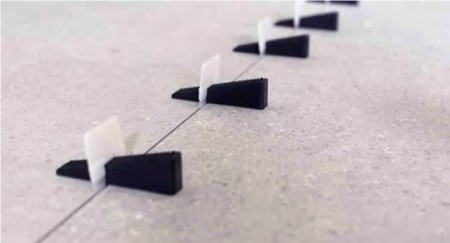

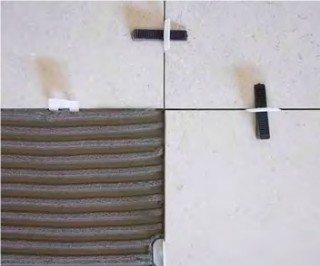

The auto-leveling spacer system is recommmended:

1

2

3

4

- Spread the adhesive over the leveled floor where you are going to install the tiles.Spread the adhesive over the back of the tile so that both the tile and the substrate are covered. In order to ensure that the mínimum thickness of adhesive is used and that it is evenly spread, always use an adhesive comb of 10mm.

- An auto-leveling spacer should be placed under the tile on the four sides. The larger the size of the tile, the more auto-leveling spaces are required.

- Fix the tile and gently tap it down into place with a rubber mallet.Insert the wedges and squeeze them into place adjusting them with the plyers without exceeding the breaking point.

- Once the adhesive is dry, you can remove the wedges by hitting them with a rubber mallet or with a kick in the direction of the grout.